If you think of cars and greenhouse gas emissions, the odds are that you will picture fumes coming out of exhaust pipes. That mental image is, of course, justified. In 2022, cars and vans were responsible for 10% of global energy-related emissions.

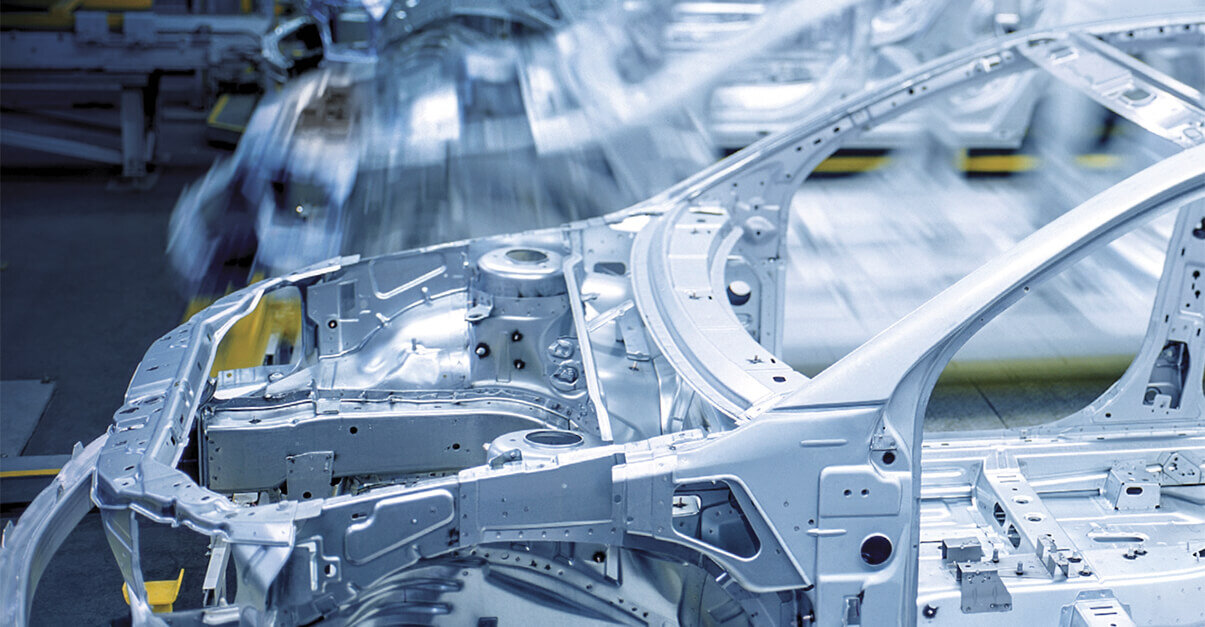

But it is not only driving vehicles that releases CO2. Making automobiles is also carbon intensive. Everything from aluminium casting to powering assembly lines demands energy and expels greenhouse gases. However, some future-minded manufacturers have their sights on low-emissions car production.

thyssenkrupp Automotive Technology, one of the five business segments of the German group thyssenkrupp AG, is cutting its greenhouse gas output with a conviction to rein in global heating. “We take our duty to reduce emissions very seriously,” Ferdinand Wieland, Senior Vice President of Procurement and Supply Chain Management at thyssenkrupp AT, says. “We are committed to the goals of the Paris Agreement and are working to make this happen – to stop climate change.”

Ferdinand Wieland (right) with Madeleine Mowinckel, Ecohz' Head of Advisory and Services (left), and Preben Munch, Senior Director of Sales and Solutions, while recording upskilling videos for thyssenkrupp AT's procurement team.

Ferdinand Wieland (right) with Madeleine Mowinckel, Ecohz' Head of Advisory and Services (left), and Preben Munch, Senior Director of Sales and Solutions, while recording upskilling videos for thyssenkrupp AT's procurement team.

Thyssenkrupp AT is a major player in the carmaking industry. It has close to 90 manufacturing sites on four continents, where it produces car components that spin in the chassis and motor of top-brand automobiles. Many of these clients have climate targets. “Customers were asking us to set emissions reduction goals,” Wieland continues. “Many have clear requirements regarding Scope 1 and 2 emissions, but also on Scope 3. We decided to start walking our own path to climate neutrality.”

A global puzzle: sourcing renewable energy around the world

Global presence has advantages. But when it comes to transitioning a company to clean energy, geographical spread comes as a challenge, too. “Back in 2022, we made our first analysis of the renewable energy market and realised we had some issues,” Wieland relates. “For example, our local energy providers in Mexico were in no position to supply us with green energy. We needed something to cover that consumption, but we didn’t know what.”

Thyssenkrupp AT aims to use 100% renewable electricity by the end of 2024, which will cut 90% of its total Scope 1 and 2 emissions, including in countries such as Germany, China, the US, and Mexico.* Each location, however, demands a different approach. “When we started, we knew how to talk to our local energy provider and switch to a green energy agreement. But this doesn’t work in every country. We didn’t know if this was the most affordable solution either.”

The German firm partnered with Ecohz to create a roadmap with the most suitable renewable energy solutions per location, including Energy Attribute Certificates (EACs), renewable gas, and on-site power generation. Ecohz Net Zero Advisors also provide thyssenkrupp AT with guidance on emerging regulations. Over the past year only, the EU and the US adopted new rules for corporate disclosure of renewable energy consumption. RE100, the global initiative of renewable energy buyers, also released new criteria for purchasing renewables.

A global perspective is essential to reach clean energy goals. But to achieve true carbon impact, companies must look beyond their own operations and come to grips with entire supply chains.

How to shift supply chains to renewable energy

“Scope 3 is a different animal.” When Ferdinand Wieland and his team started looking at decarbonising thyssenkrupp AT’s supply chain, they uncovered a behemoth. “Based on our first estimations, we think Scope 3 represents more than 90% of our total emissions,” he says.

Supply chain decarbonisation is notoriously difficult because of the complexity and scale of sprawling supplier networks. Information is hard to obtain and verify; emissions are tricky to quantify. Then comes getting everyone on board. Explaining to suppliers why they should engage in costly and often obscure emissions reduction efforts is not straightforward. So, thyssenkrupp AT asked themselves: how can we help them and not only push them?

They decided to lead by example. “We want to show our suppliers that we take climate action seriously and start with our own emissions,” Wieland continues. “We also talk with them to understand if they will support us. Will they commit to the targets? Are there different views? If so, maybe we can change their minds.”

Ecohz has supported thyssenkrupp AT in advancing its Scope 3 efforts. During a mini-conference at the German company’s headquarters in Essen, Ecohz Net Zero Advisors helped Wieland’s team with input on how to get supply chain decarbonisation off the ground. “They spent the whole day with our sustainability team to help us understand what EACs are and how these markets work,” Wieland adds. “For us, it was definitely the right decision to partner with Ecohz.”

The value of a good advisor for reducing emissions

When Ferdinand Wieland travelled to Oslo, it was not only for a social visit. He arrived at Ecohz’ offices to record a series of upskilling videos, along with three senior Ecohz advisors, to help his team back in Germany get a handle on procuring renewable energy.

"They really take you step by step into that journey and explain everything in detail. There is a lot of patience, a lot of expertise and, for sure, all the experience to show us how this can work.”

“We have around 80 locations, each with their own procurement teams. However, we want to source renewables centrally, which means we must do it very professionally,” Wieland explains. “We made this upskilling material to ensure everybody understands what EACs are, how they work, and future opportunities Power Purchase Agreements could give us.”

The series of videos is meant to make the lives of those involved in thyssenkrupp AT’s energy transition easier. Bite-sized audio-visual material will summarise long reports and help everyone get up to speed with a fraction of the effort.

That idea – simplifying complexity to get everyone on board – runs through Ecohz’ entire advisory process. “They really take you step by step into that journey and explain everything in detail,” Wieland says. “There is a lot of patience, a lot of expertise and, for sure, all the experience to show us how this can work.”

“There is no option, we want to use 100% renewable energy in our own factories in 2024 and want our suppliers to do the same by 2035,” Wieland concludes. A long road lies ahead, but thyssenkrupp AT is confident about reaching its targets with the help of a knowledgeable guide.

* Not all business units within thyssenkrupp AT have commited to the same goals and timelines. The Business Units Automation Engineering, Forged Technologies and Springs & Stabilizers are developing their own climate targets.

.png?width=3840&height=2560&name=Sun(1).png)

.png?width=3840&height=2560&name=Landscape_2(1).png)