Renewable energy for Scope 3

Switching to renewable energy is the most efficient way of decarbonising your supply chain. Ecohz has developed a service designed to cut Scope 3 emissions and enable your suppliers to easily purchase clean energy.

What does the service include?

Ecohz becomes your partner and guide throughout your decarbonisation journey, from mapping energy consumption in your supply chain to reporting reduced emissions.

The programme comprises three modules which can be provided independently to make the service fully customisable.

1. Scope 3 Advisory

The aim is to get you going. We collect the necessary data to start reducing emissions, striking the right balance between accuracy and efficiency, while working on a strategy for constant improvement.

Our advisors choose the methodology that best suits your case to understand the energy usage all through your Scope 3. Together, we set targets, identify priority areas, and help you engage your supply chain partners.

2. Supplier upskilling

We know how important it is to get your suppliers on board with your emissions reduction efforts. Through webinars, presentations, and meetings with experts, we provide them with all the information they need to ease into the procurement of renewable energy.

Our international team can provide local expertise in a number of countries and produce upskilling activities in English, Mandarin, Spanish, French, and more.

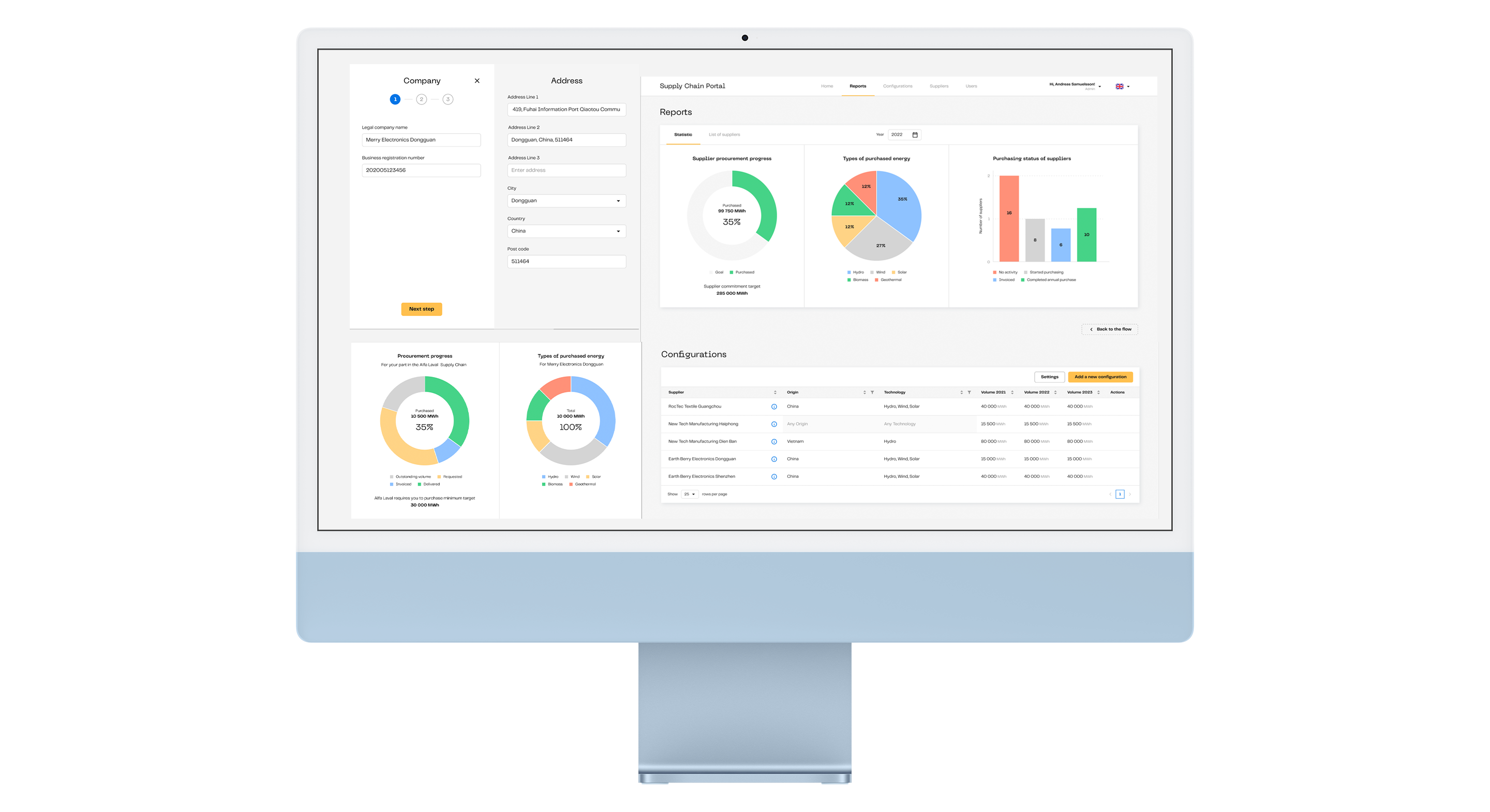

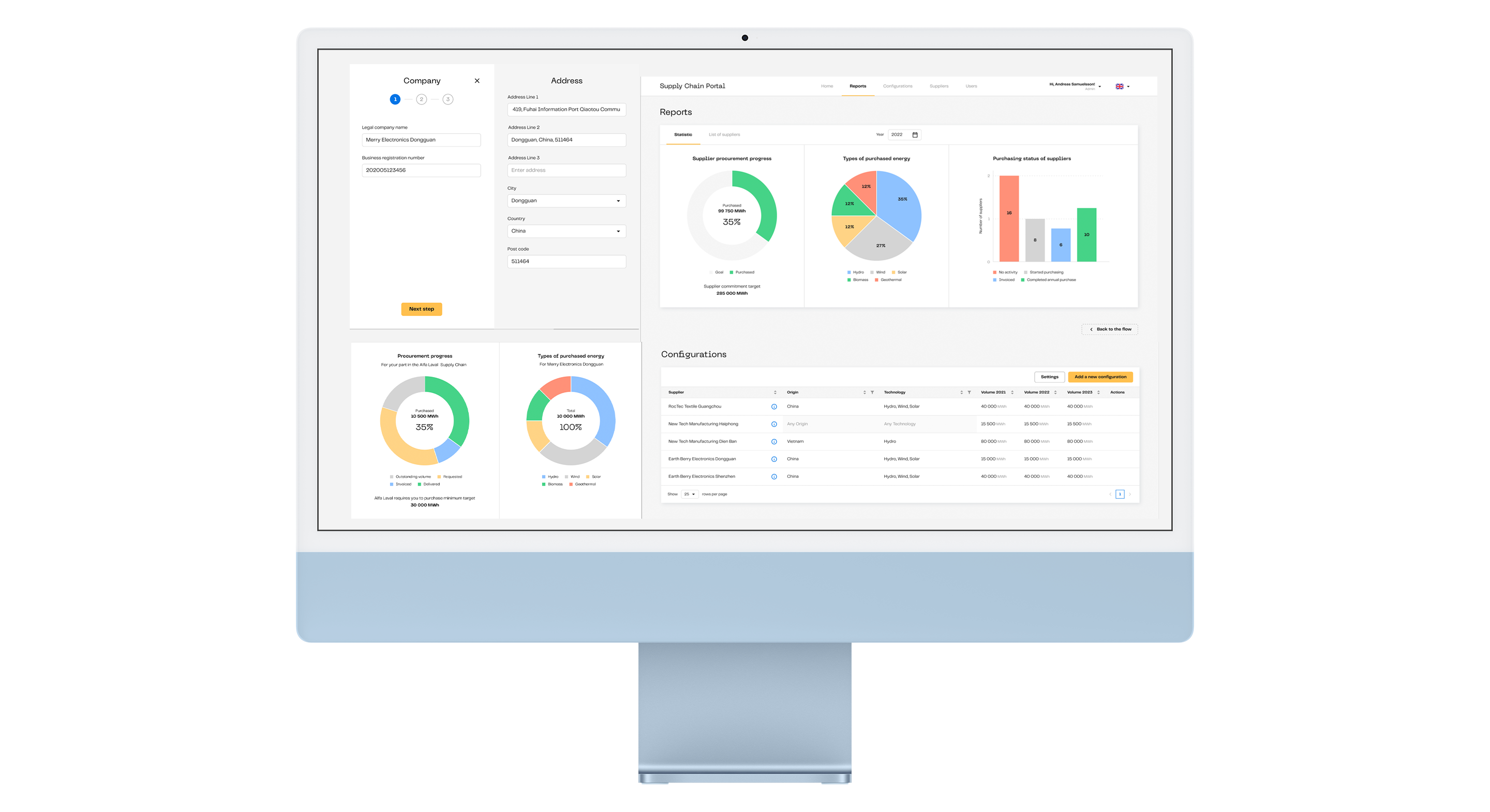

3. Supply Chain Portal

Ecohz’ digital platform streamlines the purchase of renewable energy for your suppliers. The Supply Chain Portal enables transactions of renewable electricity, biogas, carbon credits, and green hydrogen.

With the Supply Chain Portal, you can:

- Set renewable energy targets for your suppliers.

-

Enable your suppliers to easily buy and get renewable energy delivered, all on the same platform.

-

Visualise progress and produce detailed reports.

Ecohz’ experts guide and assist you every step of the way. Supply Chain Portal users receive technical support in English and Mandarin, while our advisors are always available to support you in all your value chain locations.

Ongoing support

Whenever you need us, we are here. Whether you have questions about the process, want to revise your objectives or wish to scale up your commitments, we will guide you to the finish line and beyond.

Why reduce Scope 3 emissions?

Most of your company’s emissions come from your supply chain. CDP estimates Scope 3 greenhouse gas contributions are 11.4 times higher than operational emissions, meaning there is an enormous potential for decarbonisation.

Businesses can create cascading positive impact, compelling partners to cut CO2. Regulation such as the Corporate Sustainability Reporting Directive in Europe and the Climate Corporate Data Accountability Act in California now mandates organisations to report on their Scope 3 emissions, making it more urgent than ever to act.

Why Ecohz?

Ecohz is here to make reducing emissions easy. We have 20 years of experience in the renewable energy space and provide expert guidance to corporate clients worldwide.

Using our deep knowledge of the renewable energy market, we guide organisations step by step to their climate goals and tailor solutions that deliver their climate goals.

Ecohz Supply Chain Portal

Most of your company's greenhouse gas emissions come from your supply chain. Ecohz developed a digital platform that enables companies to reduce Scope 3 emissions and gives suppliers easy access to documented renewable energy.

Webinar: Mastering Scope 3 on the way to net zero

We discussed how to get an overview of your Scope 3 and guide your value chain partners in a renewable energy transition.

Do you want to know more about our products and services? Let's have a chat.

Get in touch

Bjørn Erik Myrland

Supply Chain Portal Manager

Madeleine Mowinckel

Net Zero Advisor

Get our latest news and insights to your inbox

Subscribe to our monthly newsletter to get first-hand market analysis and intelligence on sustainable solutions for your company.

.png?width=1644&height=1191&name=Food%201(1).png)

.png?width=1644&height=1191&name=Supply%20Chain%20(1).png)

.png?width=1644&height=1191&name=Supply%20Chain%205%20steps%20(1).png)